A series article to learn about kitchen knives was introduced before. For this time, I decided to introduce the story concerning the kitchen knife again as an extra edition newly received by all of you. The theme of this issue is “the place of production of knives”.

There is a long history of knives being produced all over the country where prosperous production is limited for a long time.

Accordingly, I tried to examine the production area of the famous Japanese kitchen knife. It is only land that has a fascinating history regarding knife making respectively. If you are familiar with singing phrases such as ‘kitchen knife made of’, if you are familiar with the production area, it might be little clues when choosing a lifelong knife.

Production Area of Kitchen Knife

Niigata · Tsubame Sanjo – From the making of Japanese nails, the forge of a blacksmith

This is the forge of a blacksmith located in the center of Tsubamesanjo, Niigata prefecture. Tsubame is in the west, near Sanjo city in the east. Although this place is famous for its hardware, its excellent smithing technology, and high quality are not limited to Japan, it is also renowned globally.

History

The genealogy of making knives in this area goes back to the Edo period. It prospered from the early Edo period as a place to create “Waka (Wakagi)”. At the beginning of the Kanonaga period, due to the repeated flooding of the Igamasagawa River flowing through the center of the Sanjo town, farmers had difficulty making a living by agriculture alone. Therefore, by inviting artisans of Japanese nail making from Edo and teaching farmers their manufacturing technology, Japanese staples will begin in this area.

After that, new smithing technology is transmitted, and the products will change from Japanese nails to sickle and kitchen knives. At the same time, smiths who inherited the technique of tradition are nurtured, and in the era of Japanese staple, the smithing industry started as a farmer’s side job also became a specialized smith.

In the Meiji era, the experts of the forge rise sharply. Along with that, merchants started to trade in hardware products, utilizing rivers, “Blacksmith City, Tsubame Sanjo” will be known worldwide. After the war, due to the introduction of molds, mass production of products progressed, the products made in Sanjo became widely distributed and came out of the country. Many manufacturers, mainly in metalworking, are gathered in Sanjo town now. Kitchen goods such as knives, utensils, living goods, gardening goods, etc., are produced widely from the instruments craftsmen’s tools and working tools.

Characteristic

There are many kitchen knives with sharpness, and their manufacturing processes range from forging, fire making, cutting, sharpening, quenching, and tempering. Depending on the material, knives that craftsmen finish one by one manually have better quality.

On the other hand, many kitchen makers pursue the balance between sharpness and durability and mainly produce kitchen knives that are easy to use for the household. Kitchen knives tend to look just like sharpness, but the ease of cleaning and good cost performance are also important points. Tsubamesanjo has many kitchen knives famous both in Japan and abroad. Production is not catching up because of its popularity. It seems that there are also super popular knives that take 1 to 2 years to reach.

Kitchen Knife Made in Tsubame Sanjo

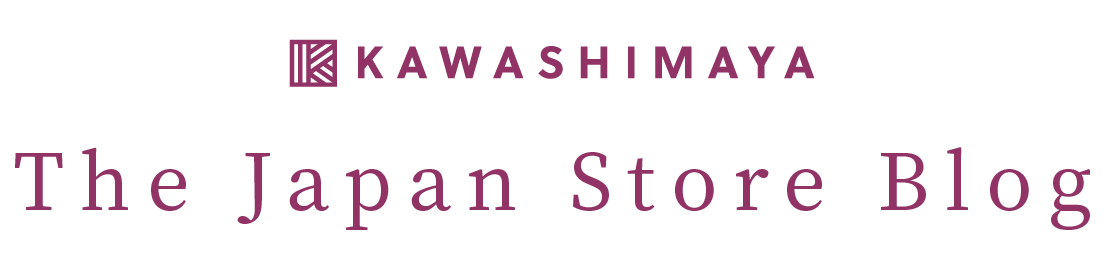

Kawamura Kenzo Manufacturing Co., Ltd. | Shitoku Kitchen knife

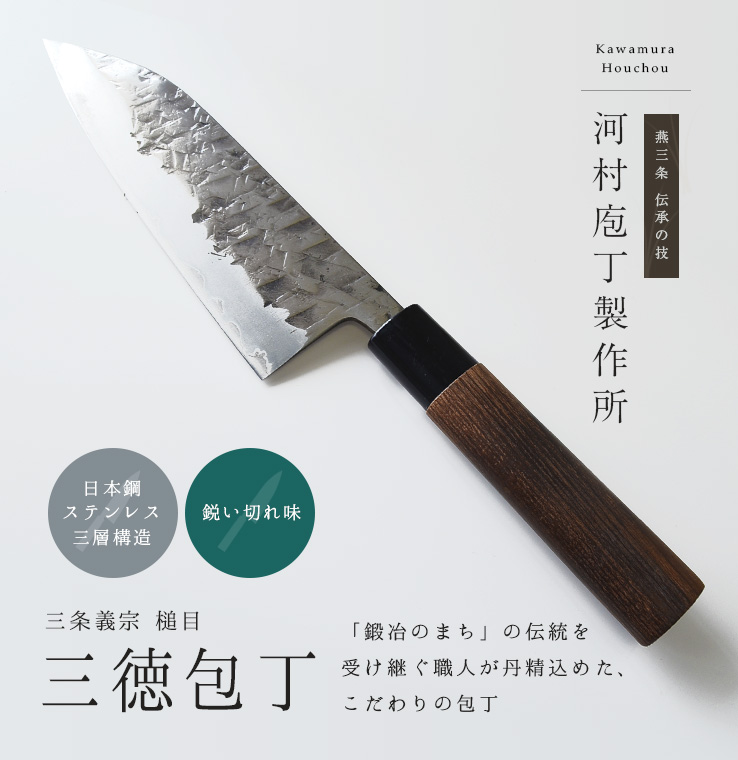

Ishikawa Seisakusho | Santoku kitchen knife

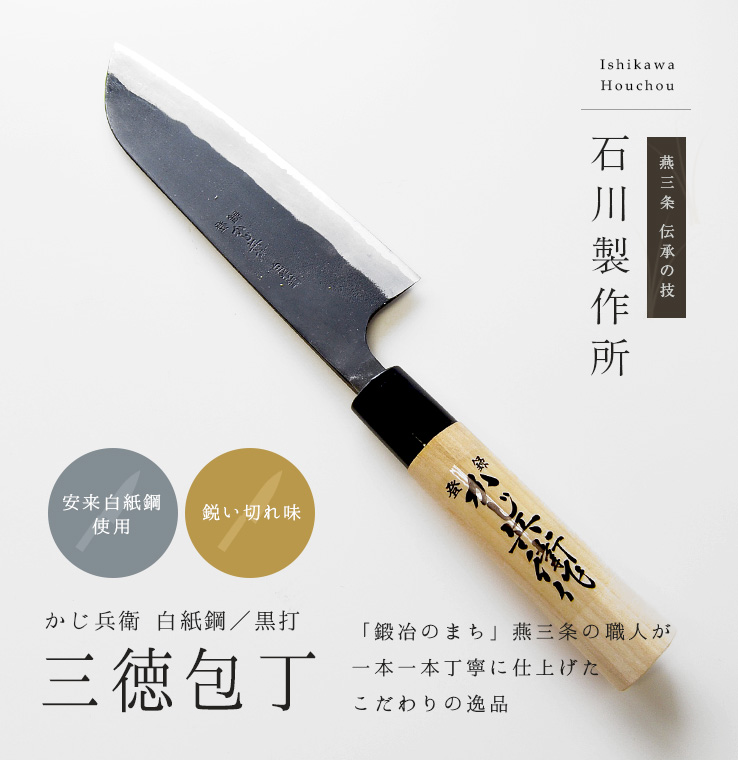

Ishikawa Seisakusho | Santoku kitchen knife

Tianyu | thin blade knife

Yihei | Rape breaking knife

Yihei | Rape breaking knife

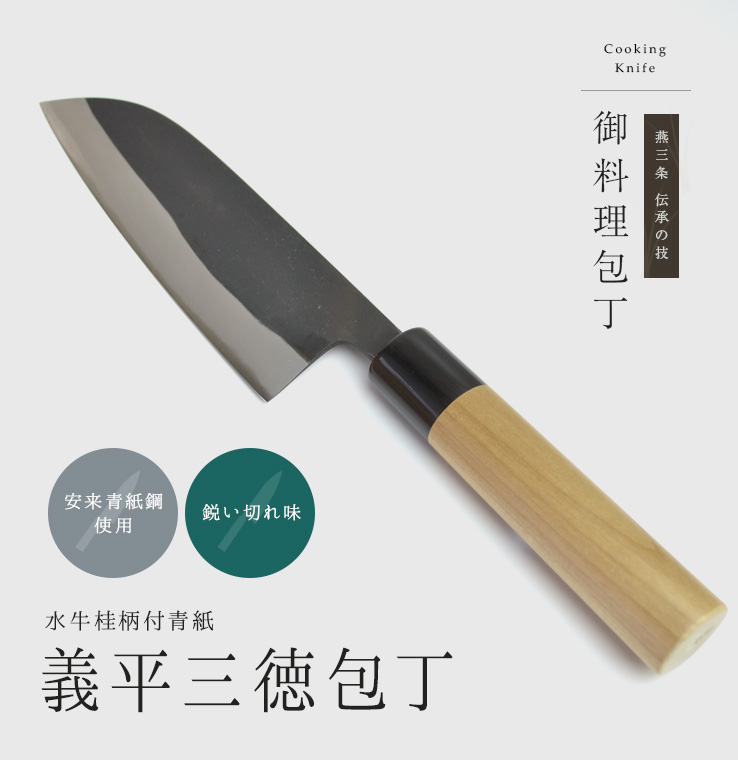

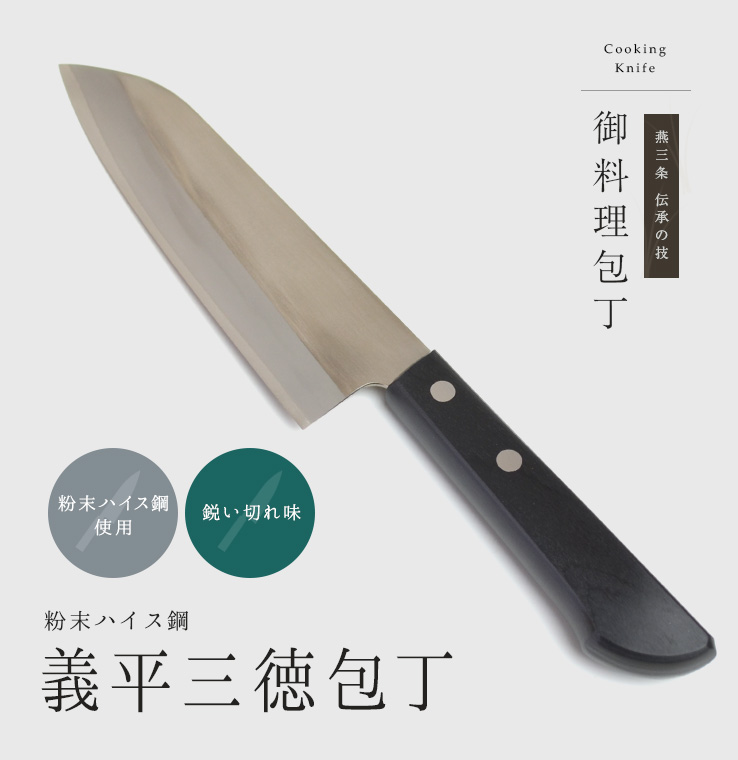

Yihei | Shintoku kitchen knife

Yihei | Shintoku kitchen knife

Gifu Prefecture · Seki City – Origin of the World’s Three Largest Knives, Which Produced Numerous Swords

Seki City, in Gifu prefecture, has developed a unique sword method of Japanese sword called Kanbu and has produced many famous swords since ancient times.

History

In the Kamakura period, the sword ancestor Motoshige moved to Seki and started swordsmithing. Originally, Seki was rich in high-quality burnt blade soil and pine charcoal and was blessed with the clean water of the Nagara and Tsubo rivers, making it an ideal land for swordsmiths.

More than 300 swordsmiths during the Muromachi period and Seki’s sword, which been said “not broken, not bent, and cut well,” spread its name throughout the country. Even in the war-torn world of the Warring States period, many famous swords such as Seki’s Magoroku were born, and many military commanders favored their unrivaled sharpness.

After that, Seki prospered as a production center of famous swords. The unique traditional techniques born in this area and cultivated over 700 years have been handed down to the modern swordsmith and knife industry.

Today, it is one of the three largest kitchen knife-producing areas globally and is famous as a knife shop where many kitchen knife makers line up.

Characteristic

It is said that much of the cutlery produced at Seki is made initially of high-quality pure iron steel (hagane). This pure iron steel has been used for Japanese swords since ancient times. However, although steel has excellent sharpness, it is easy to rust because it contains a lot of carbon, so it is necessary to take good care of it when using it at home.

In recent years, in Seki City, many kitchen knife manufacturers have been actively developing a wide variety of products that meet the needs of the times and are close to our daily lives. Incorporating a modern sense into traditional techniques, we are creating many new products while making world-class cutlery.

(Reference: Seki Tourism Association HP etc.)

Kitchen Knife Made in Seki

Yoshita Handicraft Design Room | Bovine sword 180

Yoshita handicraft Design Room | Bovine sword 210

Yoshita Handicraft Design Office | Petty Knife

Yoshita Handicraft Design Room | Bread Knife

Samsung cutlery | Sanfuki knife

Samsung knife | cow sword

Samsung cutlery | Petty

Samsung cutlery | Bread cut

Samsung cutlery | Parlor

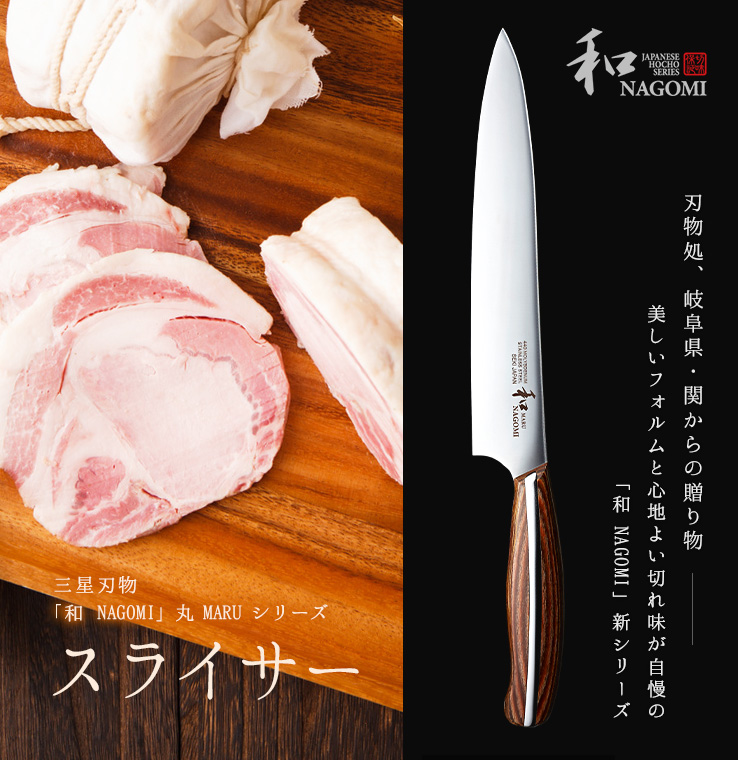

Samsung cutlery | Slicer

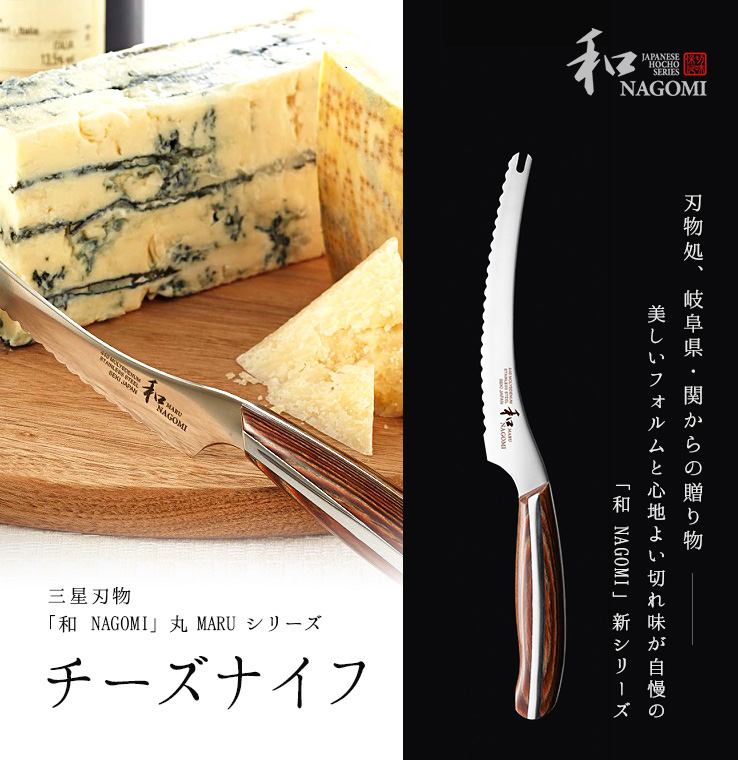

Samsung Cutlery | Cheese Knife

Samsung cutlery | cake knife

Osaka prefecture · Sakai city – Kitchen that the cooks love, Sakai knife

Osaka also has a famous production area for cutlery. A knife called Sakai Uchihamono is made in the region centered on Sakai City and Osaka City.

History

There are many ancient burial mounds in this area, including the most prominent ancient burial mound in Japan, “Nintoku Emperor’s Mausoleum”. Still, it is believed that large-scale civil engineering work was carried out during the Kofun period.

During the tumulus construction, many tools such as mulberry and skis necessary for civil engineering work were manufactured. It is said that the craftsmen continued to settle in Sakai and developed blacksmithing techniques.

When the Portuguese introduced guns and cigarettes in 1543, the technology of Sakai knives was utilized, and in the Warring States period, Sakai became famous as a production center for firearms.

After that, with the end of the war-torn world, the demand for guns decreased. In the Tensho era, instead of the smoking epidemic, “tobacco knives” that chop tobacco leaves began to be made in Sakai. IIn the Edo period, the Tokugawa Shogunate should be monopolized with the “Sakai Goku” mark. As a result, the name Sakai Uchihamono has spread all over the country.

Since then, the skill of making excellent cutlery has been handed down to the regional craftsmen. Until now, many sharp knives used by professional cooks have been produced.

The share of commercial knives made by professionals in Sakai is over 90%! From the high ratio, you can feel the pride of the Sakai Uchihamono craftsmen who continue to create authentic knives that are particular about sharpness, quality, and the trust of the cooks who bring them there.

Characteristic

To combine sharpness and durability, Sakai Uchihamono is made by adhering to two different materials, bullion (soft iron) and blade (steel). The iron used as the bullion is very soft, and the steel used for the cutting edge is steel with a high carbon content, which becomes extremely hard when hardened. Together these two kinds of materials are knocked down while making a fire, and it will fit into the shape of a kitchen knife as it blends. In this way, using a material with a hard cutting edge and soft other parts, you can make a knife that does not break, does not bend, and cuts outstandingly.

The characteristic of Sakai Uchihamono is its “sharpness”. It is created by forging and sharpening techniques by skilled craftsmen who have inherited the traditional methods. Mr. Itamae’s knives have a good reputation for their sharpness, as most of them are said to be Sakai knives.

(Reference: Sakai Cutlery Commerce Industry Cooperative Association HP etc.)

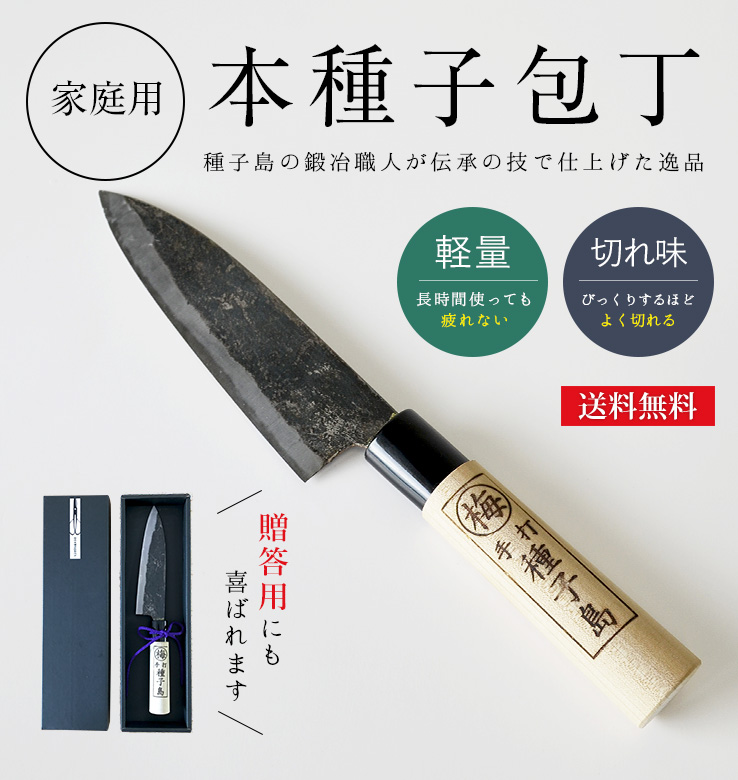

Kagoshima prefecture · Tanegashima – Seed kitchen knife born from gun smithing

History

Since the Portuguese brought guns to Tanegashima in 1543, matchlock guns have flourished, and a blacksmithing technique has developed.

After that, with the change of the times, things changed to “scissors” and “kitchen knives” used at home, and the blacksmithing technique was handed down to the blacksmiths of Tanegashima. Currently, items called “seed shears” and “seed knives” have been designated as “traditional crafts” by Kagoshima Prefecture and are highly evaluated as Tanegashima’s specialty products.

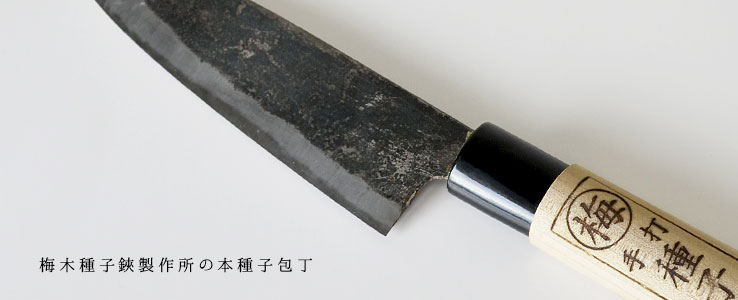

Characteristic

“Seed knives” are usually forged by carefully hand-making hot iron one by one and taking time. Its feature is its sharpness. The thin blade created by Tanegashima’s traditional blacksmithing technique is delicate and cuts surprisingly lightly. The sharpness is convincing that professional cooks and culinary researchers highly evaluate it.

Nowadays, the number of craftsmen who can forge decreases, and the number of “seed knives” is limited. It is difficult to obtain it because it is difficult to see it even at a kitchen knife specialty store.

Kitchen Knife Made in Tanegashima

Umeiki this seed scissors factory | this seed kitchen knife

This time, as “Learn Kitchen Knives: Extra Edition”, we introduced the famous places where kitchen knives are produced.

How was it?

In each place, history became the genealogy leading up to the current kitchen knife making.

After all, making kitchen knives cannot be done overnight. I felt once again that the craftsmen needed the traditional skills and know-how that they had inherited from their predecessors. We hope that it will be helpful to everyone as a bit of knowledge about kitchen knives.

You can also read all four articles on “Learn Kitchen Knives” from the links below. Please take a look!